Stereolithography : the process

Stereolithography is one of the most detailed methods of rapid prototyping and 3D printing currently available. It is also known as SLA or SL with the file extension .stl being drawn from this abbreviation.

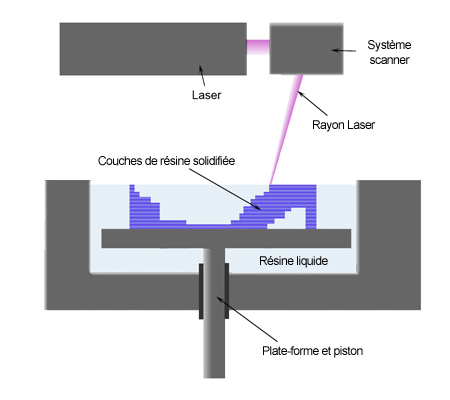

This process is an additive manufacturing procedure which uses a receptacle of liquid ‘stereolithography resin’ photopolymers (a substance which solidifies on exposure to an ultra violet laser. The 3D model is built layer by layer, on a mobile platform. The laser touches the container solidifying the parts required to achieve the creation of the SLA prototype.

source: materialgeeza via Wikipedia

source: materialgeeza via Wikipedia

When a layer is completed the mobile platform upon which the solid layers are placed is lowered by a distance which is equal to the thickness of each layer of material being used (usually between 0.05 mm and 0.15 mm).

This exposes a liquid surface once more, enabling the laser to begin tracing it again in order to create a new layer which will be placed directly on top of the one below it. Once the process has been completed, the printed 3D object is then rinsed in a chemical solution in order to cleanse it of excess resin. Following this, it is then ‘baked’ in an ultra violet oven in order to harden it.

Stereolithography: technical characteristics

| Technology | Stereolithography |

| Abbreviation | SLA |

| Materials used | Liquid polymer |

| Available Materials | Thermoplastic (Elastomers) |

| Maximum printing size | 150 cm x 75 cm x 50 cm |

| Maximum resolution | 0,00254 cm |

| Tolerance | +/- 0,0127 cm |

| Finish | Smooth |

| Printing speed | Medium |

| Applications | - Form/fit testing - Functional testing - Rapid tooling patterns, Snap fits, Very detailed parts, Presentation models, High heat applications |

Stereolithography: advantages

###A rapid process

Stereolithography is a manufacturing procedure which takes a short time to complete and it is possible to create functional products within a day. The manufacturing periods for procedures involving stereolithography vary according to the size and complexity of the object being produced with differences ranging from a few hours to slightly over 24 hours. The average dimensions of 3D printing platforms used in Stereolithography are 50 cm x 50 cm x 60cm; there are however large printers capable of printing objects up to two metres in height ### Durability of products created from the stereolithography process

Items created using stereolithography 3d printers are sufficiently durable for processing or for use as plastic injection molds, thermoforming and in casting processes.

Stereolithography: applications

Stereolithography can be used for:

- Adjustment and size tests.

- Obtaining finished products (painting, texture) for market tests

- Producing molds for processing purposes or mold patterns for vacuum casting

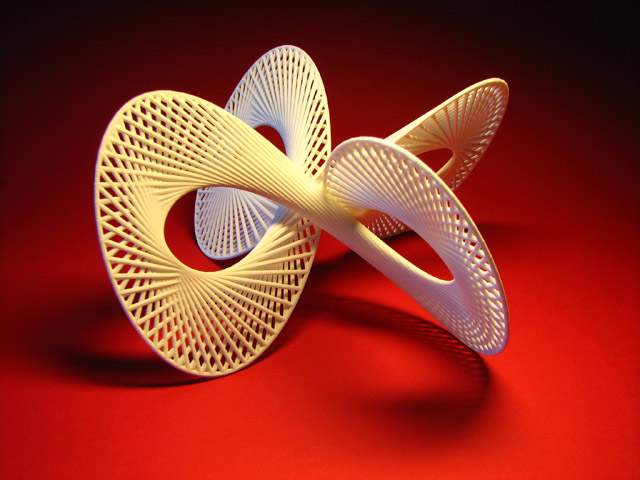

source: fdecomite via Flickr

source: fdecomite via Flickr

Stereolithography: costs

It is a relatively expensive process. The liquid ‘stereolithography resin’ photopolymers required may range from 70 to 220 euros, while stereolithography printers cost 100 000 euros and above.

Stereolithography: background

Was invented in 1986 by Charles W. Hull. He also founded the 3d society which is responsible for patenting the procedure.