The 3d metal printing process is becoming increasingly commonplace particularly in manufacturing industries throughout the world with titanium and stainless steel being the most widely used metals. 3d metal printing equally makes it possible to manufacture objects from precious metals such as gold, silver and bronze through the creation of molds into which the precious metals are then injected.

The site Shapeways offers stainless steel from prices starting at 8.00 $/cm³ with additional charges of $6 for handling (it is $7.50 for bronze plating and up to $9.00 for gold).

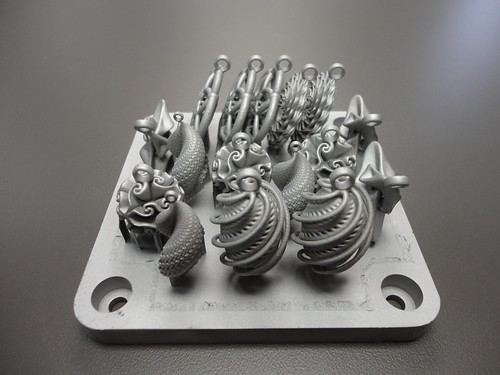

##3d metal printing and steel Stainless steel was one of the first 3d print metals to be used in 3d printing process. It possesses favourable mechanical properties and is resistant to corrosion. Stainless steel is mainly used in the aerospace industry for rapid metal prototyping of durable, high resistance objects.

Un des premiers métaux d’impression 3D disponible, l’acier ou acier inoxydable (inox) d’imprimante 3D possède de bonnes propriétés mécaniques et une haute résistante à la corrosion. L’inox est principalement utilisé dans l’aérospatiale pour le prototypage rapide métal de pièces solides et hautement résistantes.

source: Shapeways via Flickr

source: Shapeways via Flickr

##3D Printer & Aluminium Aluminium and particularly its alloy AlSi10Mg (a typical flow alloy) is used for geometrically complex objects with slender lines. It is durable and highly resistant and possesses additional favourable properties make it a popular choice in manufacturing objects subjected to high charges. 3d aluminium printing is ideal for producing objects which have favourable thermal properties and low weight.

source: Puzzleparadox via Flickr

source: Puzzleparadox via Flickr

##Titanium 3d printing Titanium (and its alloys) is a 3D printing material which is durable, light and resistant to corrosion. It is mainly used in the field of medicine, the aerospace, automobile and chemical industries as well as heavy industries. Titanium and particularly the alloy, Ti6Al4V is used in Titanium 3d printing in the form of fine metallic powder and possesses favourable mechanical properties and is resistant to corrosion. It is also biocompatible and is ideal for a wide range of high performance engineering applications such as aeronautics and automobile racing as well as the production of medical implants. Objects produced by 3d titanium printers adhere to ASTM F1472 standards ensuring they possess very low levels of impurities.

source: iMaterialise via Flickr

source: iMaterialise via Flickr

##3d gold printing The 3D printing of precious metals such as gold and silver does not involve the direct printing of these materials using a 3d printer but is carried out using a wax mold created by the 3d printing process which is then filled with the precious and the object is created by lost wax casting. It is then finished by hand and polished. The practice of creating objects using this method is widespread in the jewellery and the luxury items industries.

source: Shapeways via Flickr

source: Shapeways via Flickr

##3d cobalt printing Cobalt chrome alloys are widely in the medical industry for creating medical prostheses or dental crowns due to their precision and smooth appearance. Cobalt chrome alloys are also resistant to heat and wear making them ideal for use in high temperature engineering and the manufacturing of turbines.

source: Dizingof via Flickr

source: Dizingof via Flickr

##3D metal printing technologies The main technologies used in 3D metal printing are laser sintering using powdered metal and E Beam technology developed by the enterprise Arcam.

source: Shapeways via Flickr

source: Shapeways via Flickr